In today’s competitive market, branding is everything—and custom rolling papers are one of the most underused but powerful tools for branding. Whether you’re a dispensary, influencer, musician, or brand, custom printed rolling papers are a cost-effective way to stay in your customer’s hands (and minds) every time they light up.

But how do you actually make custom rolling papers?

Let’s walk through the full process from the manufacturer’s perspective—including all the techniques, materials, formats, and customization options available.

The base material is the soul of your custom rolling paper. There are several types to consider:

| Rolling Paper Material | Pros | Cons |

|---|---|---|

| Wood Pulp Rolling Papers | Burns evenly, widely accepted, good for mass production | Not the cleanest smoke |

| Hemp Rolling Papers | Eco-friendly, slow-burning, organic vibe | Slightly rougher texture |

| Rice Rolling Papers | Very thin, minimal ash, clean taste | Harder to roll, can be brittle |

| Flax/Bamboo Rolling Papers | Smooth texture, unique branding opportunity | Less common, niche appeal |

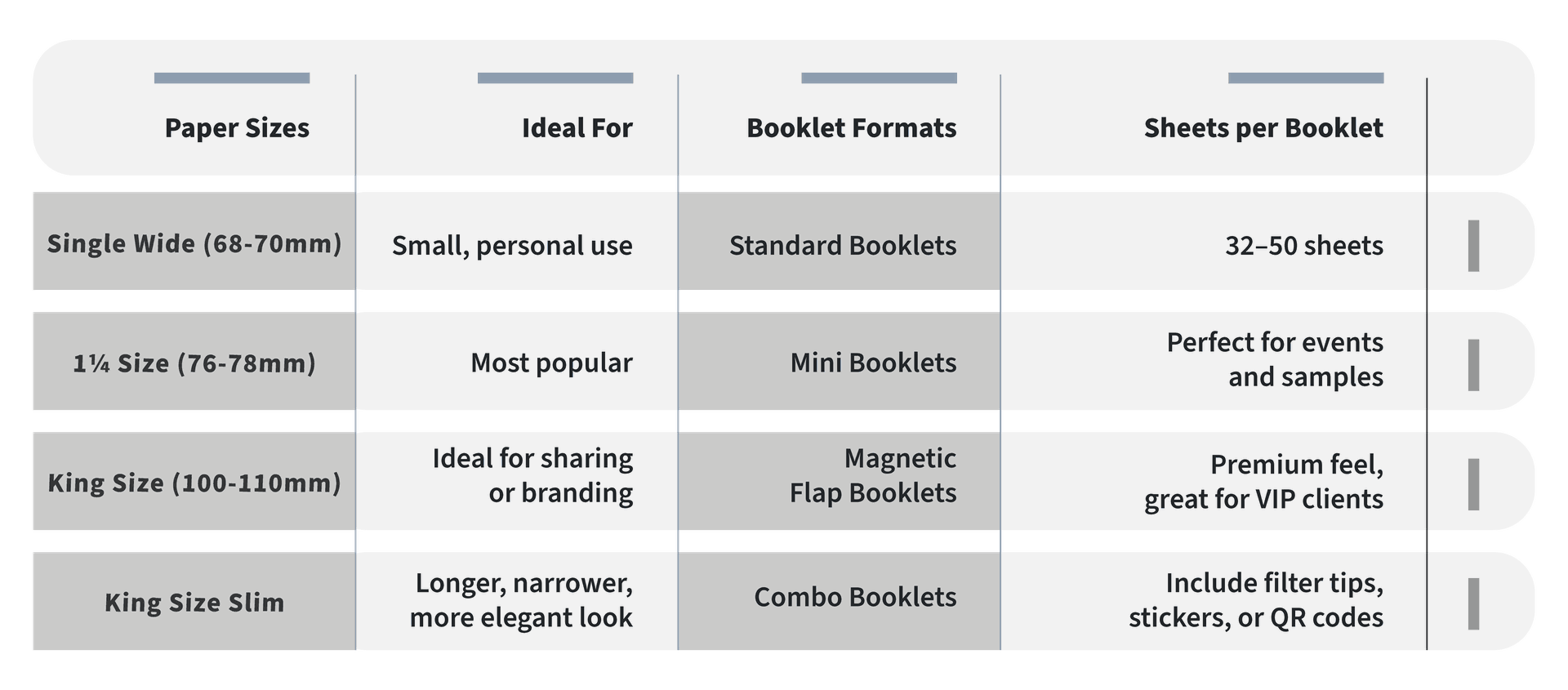

Custom rolling papers come in various sizes and formats. Choosing the right one depends on your audience and use case.

Paper Sizes

- Single Wide (68-70mm) – Small, personal use

- 1¼ Size (76-78mm) – Most popular

- King Size (100-110mm) – Ideal for sharing or branding

- King Size Slim – Longer, narrower, more elegant look

Booklet Formats

- Standard Booklets – 32–50 sheets

- Mini Booklets – Perfect for events and samples

- Magnetic Flap Booklets – Premium feel, great for VIP clients

- Combo Booklets – Include filter tips, stickers, or QR codes

This is where branding meets creativity. There are several ways to print on rolling papers—and each has its own benefits.

Printing Methods

Method |

Pros |

Cons |

|---|---|---|

| Flexographic Printing | Fast, good for large runs | Less color precision |

| Offset Printing | Sharp images, high quality | Better for booklet covers than on paper itself |

| Digital Printing | Great for prototypes or small batches | More expensive per unit |

| Foil Stamping / Embossing | Premium feel, luxurious design | Limited detail, not for direct contact with smoke |

Your custom rolling pepers booklet is your billboard. A compelling cover design can turn a casual user into a loyal customer.

Design Tips

- Front cover – Feature your logo, tagline, or a QR code

- Inside cover – Include educational info, quotes, promotions

- Back cover – Add social media handles, website URL

Make your booklet even more valuable by adding extras:

- Custom Filter Tips – Perforated, pre-rolled, or branded

- Stickers – Add peel-off logos or coupon codes

- Inserts – Paper slips with marketing messages or legal disclaimers

- QR Codes – Drive traffic to your online store or social media

Packaging isn’t just about aesthetics—it’s about legality and shelf appeal.

Things to Consider:

- Resealable pouches or display boxes for retailers

- Compliance labels depending on your region (California, Canada, EU, etc.)

- Barcodes and batch numbers if selling retail

| Technique | Application | Pros | Cons |

|---|---|---|---|

| Edge Printing on Sheets | Printed tips or borders on paper itself | Highly unique branding | Needs high accuracy to avoid burn issues |

| Booklet Cover Design | Full-color CMYK, foil, spot UV | Fully customizable | None if using quality printer |

| Filter Tip Integration | Pre-attached or loose tips | Increases value and utility | Slightly higher production cost |

| Custom Inserts | Marketing or legal slips | Educates user, cross-promotes | Adds assembly step |

| Stickers / QR Codes | Interactive marketing tools | Drives traffic and engagement | Can peel off with use |

- Full In-House Production – No brokers, full control

- Low Minimums & Wholesale Rates – Scalable for all sizes

- Fast Turnaround – Speedy production and delivery

- Free Delivery - Door-to-door step with tracking number

- Eco-Friendly Options – FSC-certified, hemp, soy ink

- Not Just Papers – Pre-rolls, grinders, tips & more

If you’ve ever wondered how to make custom rolling papers, now you know—it’s part craft, part marketing science, and 100% brand strategy.

At StarRolls.com and RollYourOwnPapers.com, we help brands of all sizes bring their paper ideas to life. Ready to roll?

Start your custom project today and make your products stand out.